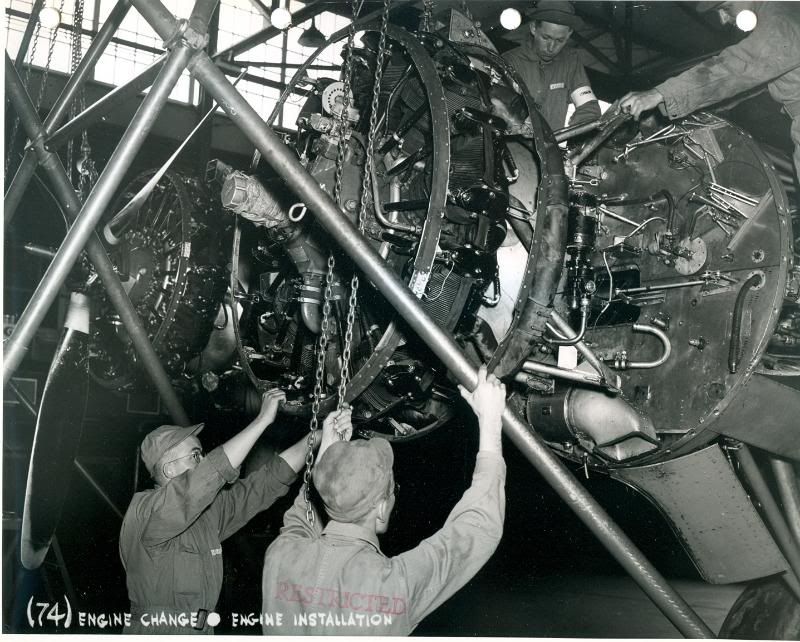

As a change of pace I worked on the engines and cowling installations for a time. I had been concerned about how I was going to get the correct gap at the rear of the cowling where it meets the nacelle. On these very early machines there were no cowl flaps, only an aerodynamic opening between the cowl ring and accessory fairings. On the real airplane the engine supports the forward cowling, independent of the rest of the nacelle. This is done by attaching two support rings, one being the aft baffle ring and the other being a plain ring attached to the front of the cylinders. Here is a photo of an engine change on a Y1B-17 from the Amarillo B-17 Mechanic School engine change "classroom". The support ring is easily seen:

Boeing Y1B-17 Project--1/48th Scale

I decided to mount the forward ring into the cowling on my model to expedite the process. I used a band of safety wire cut to the right length and made circular, then just inserted it into the cowling so that the engines will be in the correct position. In the final assembly stage I will be able to attach the engines to the firewall and the cowlings will slip onto the engines giving me the gap at the rear of the cowl ring that is needed. In that way you'll be able to see light between the cylinders when looking into the front of the cowling, just like on the real thing:

Boeing Y1B-17 Project--1/48th Scale

Now I have to build four airscoops for the oil coolers. I hope I have something in my spares or I'm going to have to scratchbuild them, and I'm not really looking forward to that prospect.

Scott